IBR & widespan ROOF SHEETING SOUTH AFRICA: SIZES & DIMENSIONS

IBR (Inverted Box Rib) and Widespan sheeting are a type of roofing material commonly used in industrial, commercial, and residential construction. It is a popular choice due to its durability, versatility, and aesthetic appeal. IBR and Widespan sheeting are typically made from galvanized steel, although other materials like aluminum and stainless steel can also be used.

The term "Inverted Box Rib" refers to the profile or shape of the roofing sheet. It consists of a series of alternating ridges and valleys, forming a high-strength structural pattern. This design provides excellent water-shedding capabilities, making IBR sheeting highly suitable for roofing applications.

We supply standard IBR Galvanized sheets, with a coverage width of 686mm, or for broader coverage needs, our Wide Span Galvanized sheets, with a 762mm effective width, are perfect for larger spans.

While IBR and Widespan sheeting are commonly used for roofing, it can also be used for wall cladding and other applications where a durable, weather-resistant material is required.

We deliver IBR and Widespan Roof Sheets throughout South Africa.

IN STOCK AT 21 BRANCHES

COLLECTION OR DELIVERY

CUT TO SIZE FOR TRANSPORT

WHY CHOOSE NJR STEEL IBR & Widespan SHEET ROOFING?

Durability

IBR sheeting is known for its strength and durability, making it resistant to weather conditions, including wind, rain, and hail. Its robust structure provides reliable protection for the building beneath it.

AESTHETIC APPEAL

The distinctive profile of IBR sheeting enhances the visual appeal of a building. It offers a clean, modern look that can complement both contemporary and traditional architectural styles. The material can also be painted or coated in various colors to match the building's design preferences.

Easy Installation

IBR sheeting is relatively straightforward to install, especially when compared to other roofing materials. Its standard profile allows for quick and efficient installation, saving time and labor costs during construction.

Water Resistance

The ridges and valleys of the IBR profile facilitate efficient water runoff, minimizing the risk of leaks and water damage. This feature is particularly crucial in areas with heavy rainfall or snow.

Cost-Effective

The longevity and low maintenance requirements of IBR sheeting contribute to its cost-effectiveness over the long term. It is a cost-efficient roofing solution that offers reliable performance and can withstand harsh conditions, reducing the need for frequent repairs or replacements.

Versatility

Available in various thicknesses, widths, & lengths to allow for customization to suit specific roofing requirements, IBR can be easily cut & shaped to fit different roof designs, making it adaptable to a wide range of architectural styles.

THE PERFECT ROOFING SYSTEM FOR YOU

CRANKING & BULLNOSING MANUFACTUREd TO YOUR SPECIFICATIONS

cost-effective option

various thicknesses & sizes AVAILABLE

Available Lengths, Installation, & Structural Considerations for IBr & widespan sheeting

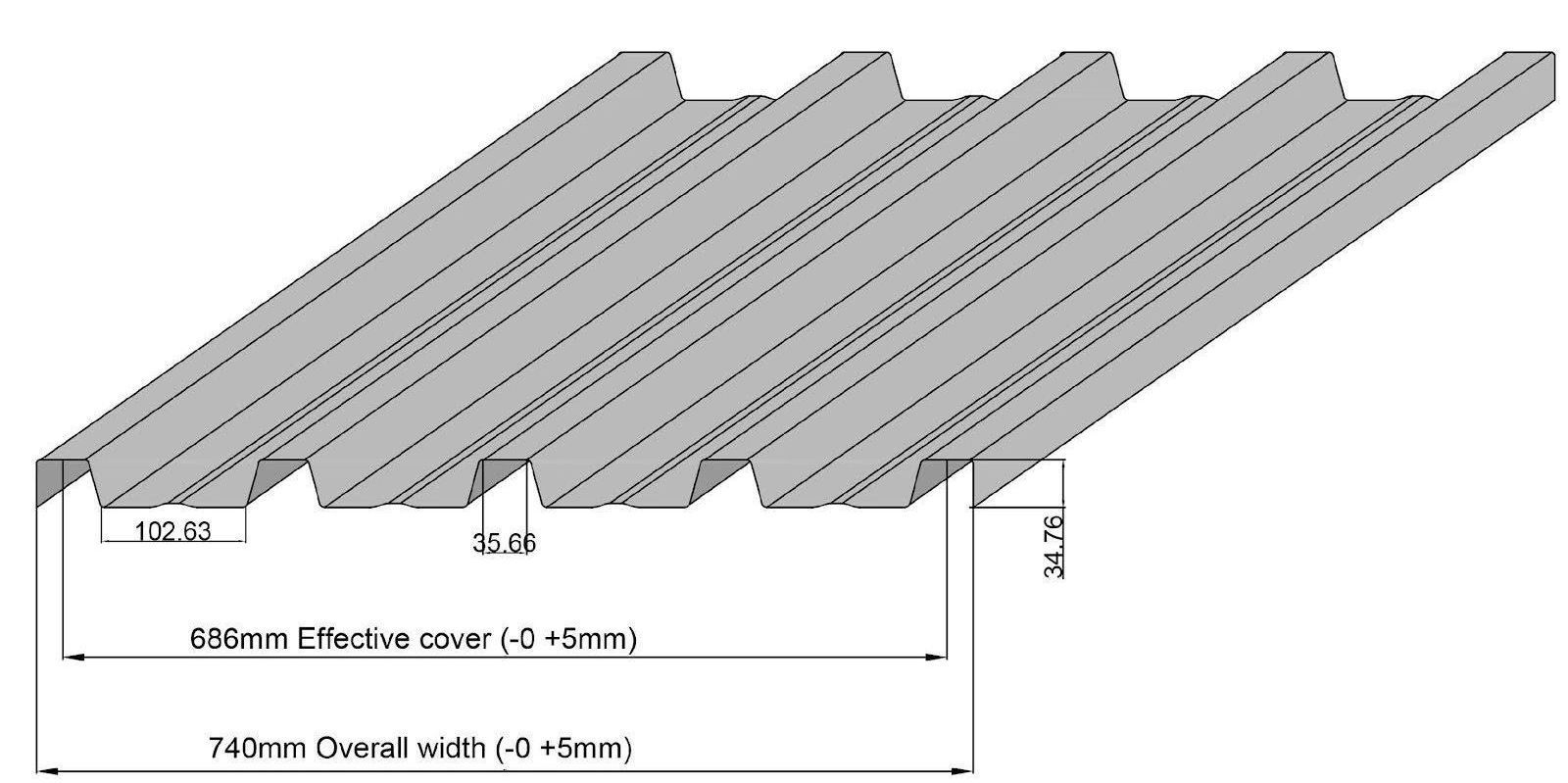

IBR 686 ROOF SHEETING

IBR is a square-fluted profile suitable for use as side cladding or roofing in commercial, industrial and residential structures. IBR sheeting can be cranked, curved and bullnosed to customer specifications.

IBR is manufactured with a stiffening rib in the broad flute in order to minimize waves in the broad flute of the profile. If sheets without the stiffening rib are specified no claims for waving (oil canning) will be entertained.

Structural capabilities

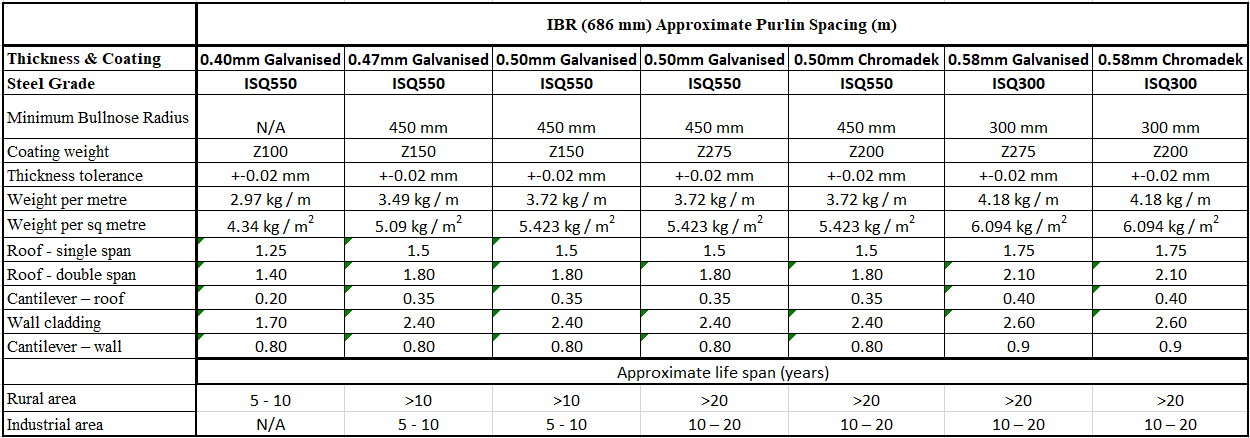

Load span characteristics are to be used as a guideline only as purlin spacing also depends on other factors e.g. the wind conditions in a certain area, the type of structure or load bearing elements such as solar geysers and panels. An engineer should determine the purlin spacing of a structure after considering the complete design. Approximate spanning capabilities of IBR is as follows:

Available lengths

IBR is available in lengths of up to 14 metres with a length tolerance of -0 +5 mm. Sheets lengths up to 15.8m are available on enquiry.

When bullnoses, cent cranks and curves are designed a maximum permissible transport height of 4.3 metres is applicable.

Roof slope

When using IBR, the recommended minimum pitch for roof slopes in excess of 15.8m is 7.5º and for slopes less than 15.8 m is 5º.

The minimum end laps for roofs pitches >15º is at least 150 mm and 250 mm for other roofs. Side cladding end laps should be at least 100 mm.

It is recommended that end laps on roofs <7.5º are sealed with a bitumen sealing strip to ensure water tightness.

Fixing procedure

The required number of IBR sheets is calculated as follows:

- Length of structure plus gable end overhangs - (minus) 70 mm

- Number of sheets = Meters required ÷ (divided by) 0.686 (Cover width of a sheet)

- The result of the calculation is the number of sheets required rounded up to the next sheet

IBR must be fixed with one corrugation side lap with the narrow flute uppermost and fastened through the crests of alternate flutes to purlins using 65 mm Tek screws into steel purlins and 90 mm Tek screws for timber roofs, each fasteners must incorporate a 25 mm bonded washer.

For side cladding broad flutes can be fixed externally with fasteners in the web of the flutes. Side cladding can be fixed using 25 mm Tek screws with a 19 mm bonded washer.

For a quick calculation 3 fasteners per sheet per purlin can be used.

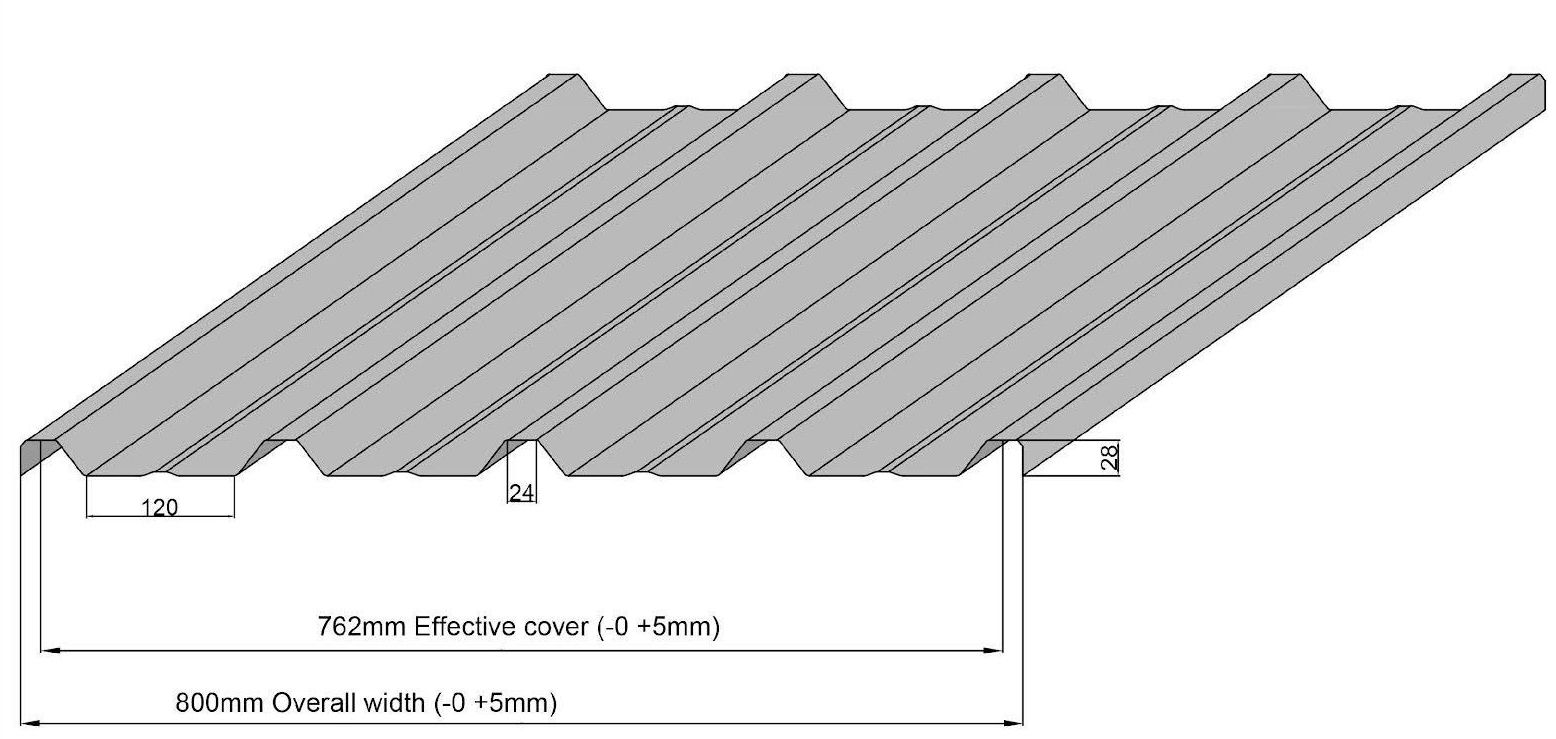

WIDESPAN 762 ROOF SHEETING

Widespan is a roofing and cladding profile designed as an economical alternative to IBR. Widespan offers greater spans and lower roof slopes than Corrugated sheeting with the same covering width. Widespan can be cranked, curved and bullnosed to customer specifications.

Widespan is manufactured with a stiffening rib in the broad flute in order to minimize waves in the broad flute of the profile. If sheets without the stiffening rib are specified no claims for waving (oil canning) will be entertained

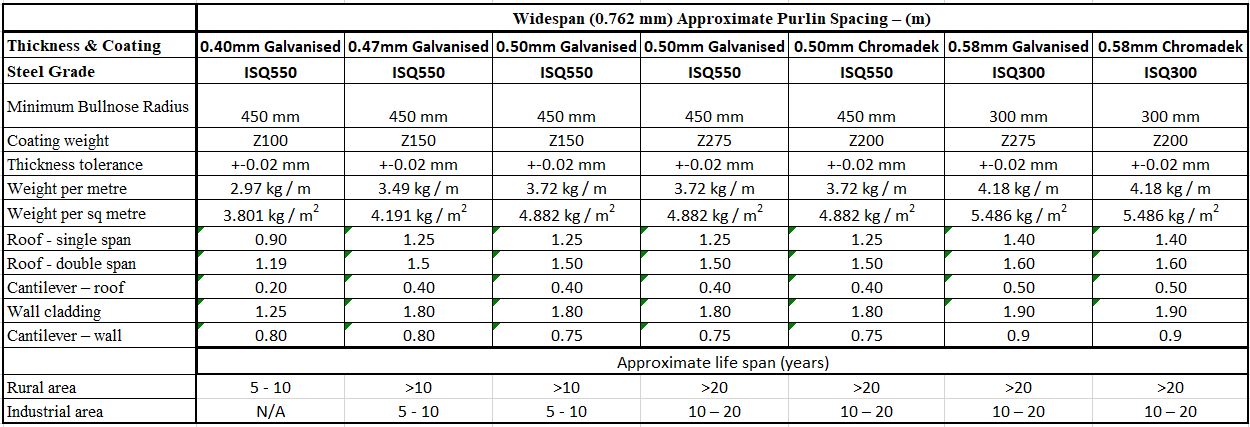

Structural capabilities

Load span characteristics are to be used as a guideline only as purlin spacing also depends on other factors e.g. the wind conditions in a certain area, the type of structure or load-bearing elements such as solar geysers and panels. An engineer should determine the purlin spacing of a structure after considering the complete design. The approximate spanning capabilities of Widespan are as follows:

Available lengths

Widespan is available in lengths of up to 14 metres with a length tolerance of -0 +5 mm. Sheet lengths up to 15.8m are available on enquiry.

When bullnoses and curves are designed a maximum permissible transport height of 4.3 metres is applicable.

Roof slope

When using Widespan, the recommended minimum pitch for roof slopes in excess of 15.8m is 10º and for slopes less than 15.8m is 7.5º.

The minimum end laps for roof pitches >15º is at least 150 mm and 250 mm for other roofs. Side cladding end laps should be at least 100 mm.

It is recommended that end laps on roofs <10 degrees are sealed with a bitumen sealing strip to ensure water tightness.

Fixing procedure

The required number of Widespan sheets can be calculated as follows:

- Length of building plus gable overhangs - (minus) 50 mm

- Number of sheets = Meters required ÷ (divided by) 0.762 m (Cover width of sheet)

- The result of the calculation is the number of sheets required rounded up to the next sheet

Widespan must be fixed with one corrugation side lap with the narrow flute uppermost and fastened through the crests of alternate flutes to purlins using 65 mm Tek screws into steel purlins and 90 mm Tek screws for timber roofs, each fasteners must incorporate a 19 mm bonded washer.

For side cladding broad flutes can be fixed externally with fasteners in the web of the flutes. Side cladding can be fixed using 25 mm Tek screws with a 19 mm bonded washer.

For a quick calculation 3 fasteners per sheet per purlin can be used.

Structural Guidelines & Considerations

- Material selection provides various structural properties, with load span characteristics serving as a broad guideline.

- Considerations include prevailing winds, rainfall, industrial particulates, and specific structure types.

- Consulting with a qualified engineer is advised to determine accurate purlin spacing for your application.

BULLNOSING, CRANKING & CURVING OF ROOF SHEETING

Offering cranking and bullnosing services, we tailor IBR and Widespan sheeting on-site to fit various architectural needs:

Bullnoses & centre cranks

Bullnosing and center cranking of a profiled sheet incorporates lateral rib indentations pressed in at uniform distances. Standard bullnoses are made with the narrow flute uppermost and the bend away from the angular inclination. Reverse bullnoses are made with the narrow flute downwards and with the bend into the narrow flute. Bullnoses and cranks can be at the end of a sheet or at any position along the length.

Bullnoses and center cranks can be done in a radius from 300 mm to 800 mm for bullnoses which are bent through 0 - 180 degrees, larger radii will be classified as a curve.

The maximum sheet length which can be bullnosed is 15 m, with a maximum height of 2 m. The minimum runout from the bullnose is 30 mm on one side with a minimum of 500 mm on the other side of the sheet.

The critical end of a bullnose must be specified in order to ensure consistent lengths.

Due to handling and transport limitations the maximum height of center and off-center cranks which can be manufactured is 2 m with a limitation of 12 m total sheet length.

0.50mm Material can only be bullnosed and cranked to a minimum radius of 450 mm.

Crank curving

IBR and Widespan materials can be crank curved with the same process used for bullnosing but with manual handling to achieve the larger radius. In the case of Chromadek sheeting the colour can be specified on either side of the sheet.

Bullnoses will be priced as curves when the radius exceeds 800 mm. The maximum height of curves which can be handled is 2 m with a maximum sheet length of 12 meters.

On-site springing of Roof Sheets

For roofs gently curved on elevation sheets may be sprung on site. However, extreme caution should be used when attempting this procedure to prevent buckling or oil canning.

Why NJR Steel Stands Out as Your Roofing Solution

Choosing NJR Steel for your roofing needs means selecting a partner committed to quality, durability, and customer satisfaction. With our comprehensive range of IBR and Widespan sheeting options, along with customization choices, we ensure that your project benefits from the best roofing materials in the industry.

For more details on our IBR and Widespan roof sheeting or to discuss your specific project requirements, please reach out to us. Our expert team is eager to assist you in selecting the ideal roofing solutions.

Trust in NJR Steel for all your roofing requirements, where excellence and customer satisfaction are our top priorities.

>

Get IBR and Widespan Pricing from your nearest branch now via Whatsapp

GET PRICING FROM YOUR

NEAREST NJR STEEL BRANCH

We have 21 branches across 7 provinces that are ready and willing to help you. Talk to us today to get pricing or just advice for your next project.

FIND A NJR STEEL BRANCH NEAR YOU

Store locator is loading from StoreRocket Store Locator Widget..