NJR Made Of Steel DIY Challenge: Top 12

NJR Made Of Steel DIY Challenge: Top 12

The NJR Made Of Steel DIY Challenge invited participants to unleash their creativity and showcase their best steel creations.

We were absolutely blown away by the incredible response, with entries ranging from impressive Braais and Gates to intricate Sculptures and Custom Furniture.

Every submission was a testament to the talent and dedication of our entrants. Each project was carefully evaluated on a 21-point structure, and after much anticipation, the winners were officially announced on October 3rd.

NJR Steel is incredibly grateful to everyone who participated in this challenge. Your creativity and tremendous use of steel have truly inspired us, and we are already looking forward to seeing what you'll create for the next NJR Made of Steel DIY Challenge in 2026.

Winner Announcement Video

Nkosana Sibeko

20 Points

"As a bike enthusiast, I've always dreamed of building my own brand of bikes with my own design touch.

Bike building has always been a passion of mine, but I could never afford to build full-blown motorbikes.

So, I built hybrid bicycles with 66cc motors, and hopefully one day I'll be able to build my own fully fledged custom motorcycles."

Nkosana's Video

Chris Van Der Vyver

20 Points

Project Description:

"Custom-made fireballs crafted from stainless steel or mild steel. I love making unique and custom items, as well as being artistic and working with steel."

My "Steel Story":

"I transform a flat steel plate into a unique piece of metal art using a plasma cutter and a welding machine."

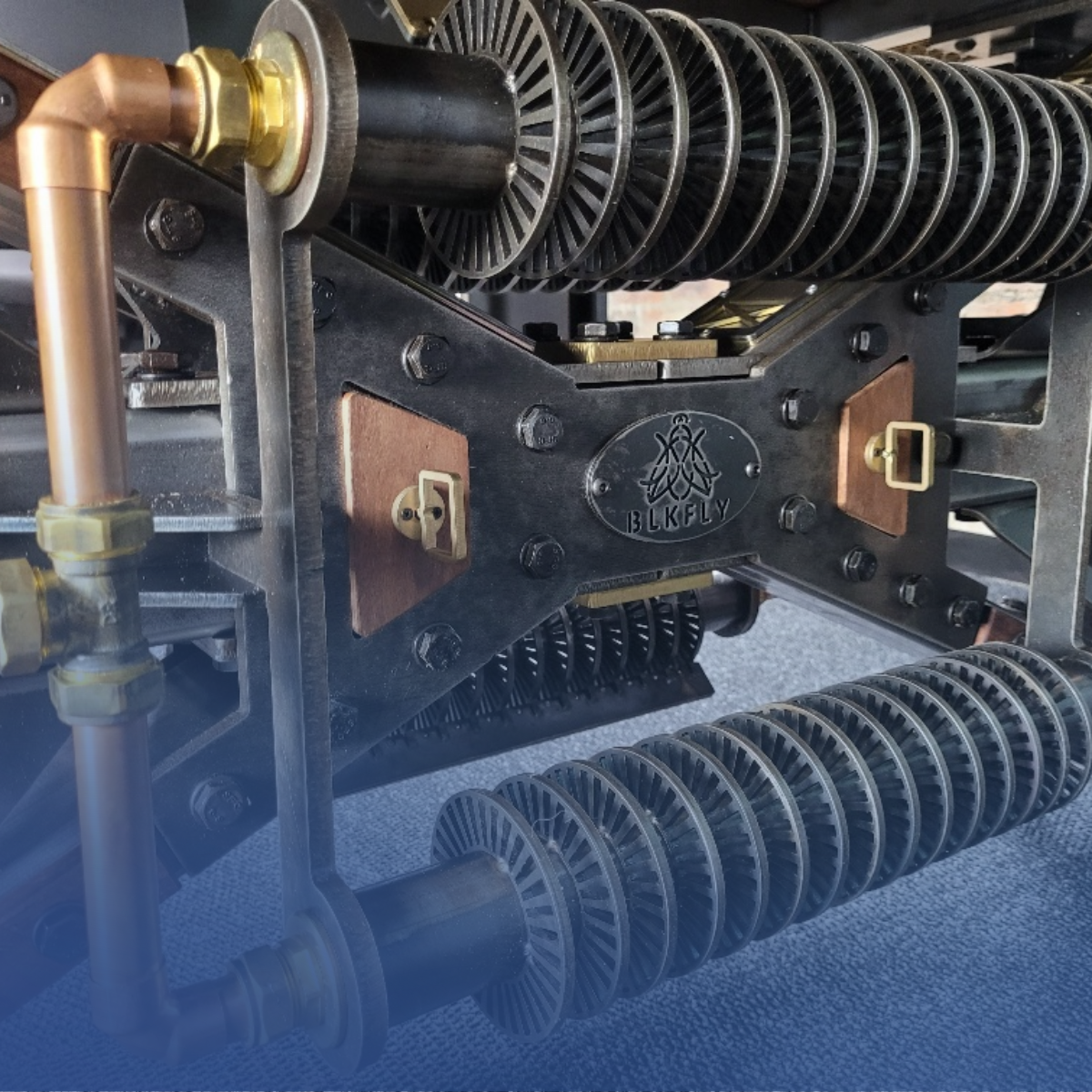

Helmuth Ridgard

20 Points

"I just wanted to share a redesigned table. This was originally designed as a dining table.

I build custom, handmade furniture as a hobby; I work in construction for a living.

I decided to share my work on Facebook, and a client contacted me asking if I'd be able to assist in his quest to revamp his company. His office is in the middle of a world-renowned art space in Johannesburg, inside the Hollard Insurance building. The whole place is decorated with art from all over South Africa.

We emailed UK-based furniture makers Steel Vintage and paid a fee to use and redesign their desk as an office desk. We only had the rights to pictures of the desk available online, and no drawings were provided, so everything was done from scratch.

With this in mind, I recruited a very talented draughtsman, and we were able to share knowledge and details about the desk. The table is 2100mm long, 900mm wide, and 850mm from the floor to the desktop. It weighs roughly 600kg, with an oak wood top and inlays. The rest is brass inlays for decoration, and the metal is still bare, but it has been treated with a self-made formula.

The theme is steampunk industrial, and the original desk was designed based on the UK flag. We had to make it "Suid-Afrikaans," so copper tubing and industrial bolts were used and TIG-welded. The welding seams are all hidden on the desk itself, but for some parts, the welding had to be visible. Button-head bolts and rivets tie all the elements together.

So, let me present my version of the UK-branded Steel Vintage's "The Kingsbridge" desk. Every part was designed from scratch; only pictures seen on the web were used.

The build time was three months, and all the angles were hand-filed."

Jarid VD Merwe

19 Points

"My father has had his farm for about five years with a very simple wire gate, so we designed and built a custom steel gate in our workshop at Taurus Tippers, combining durability with a clean, modern look.

The gate was crafted from heavy-duty steel purchased from NJR Polokwane.

It was a fun family project that brought us together, from the designing to the installation, with our fair share of challenges."

Janelle Rickhoff

19 Points

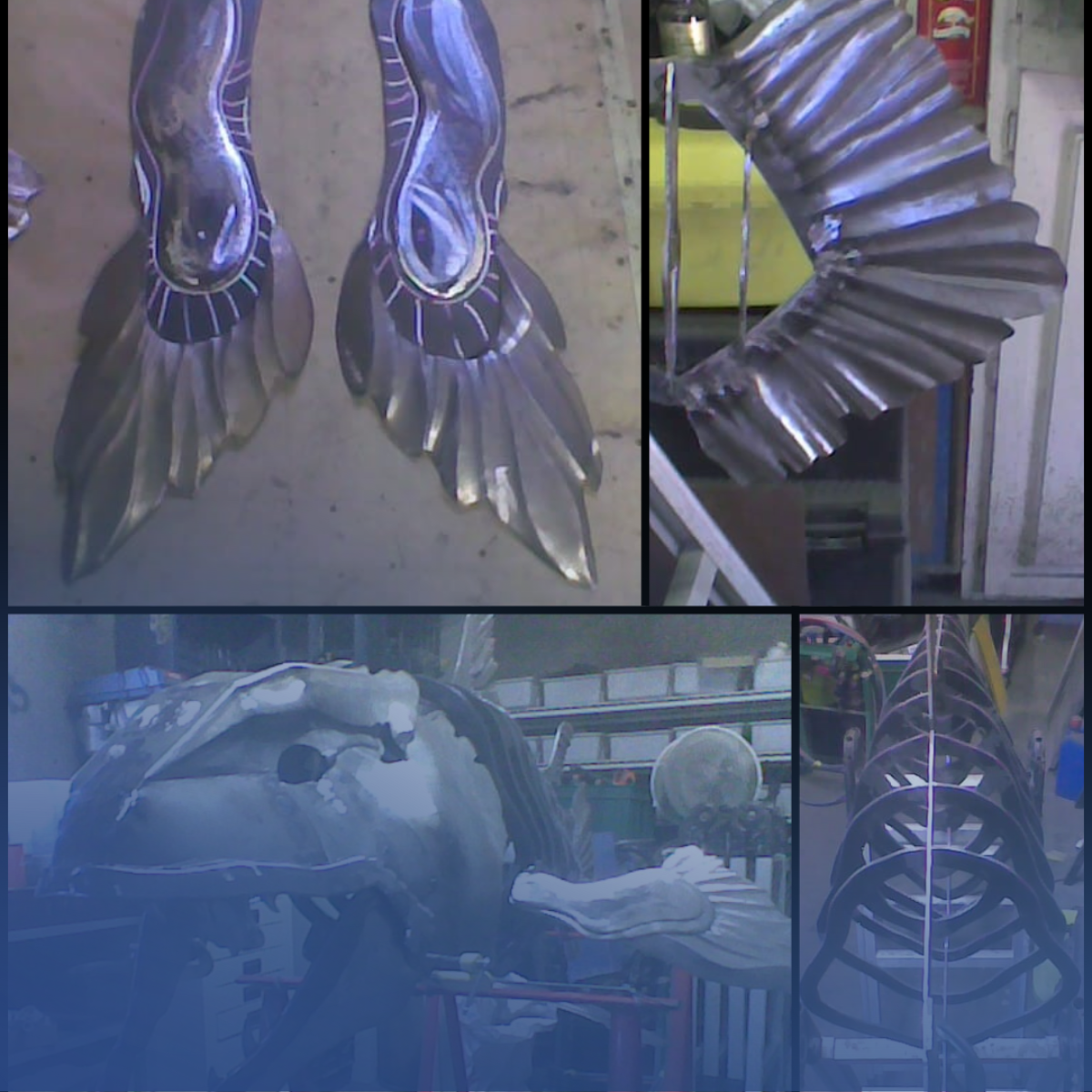

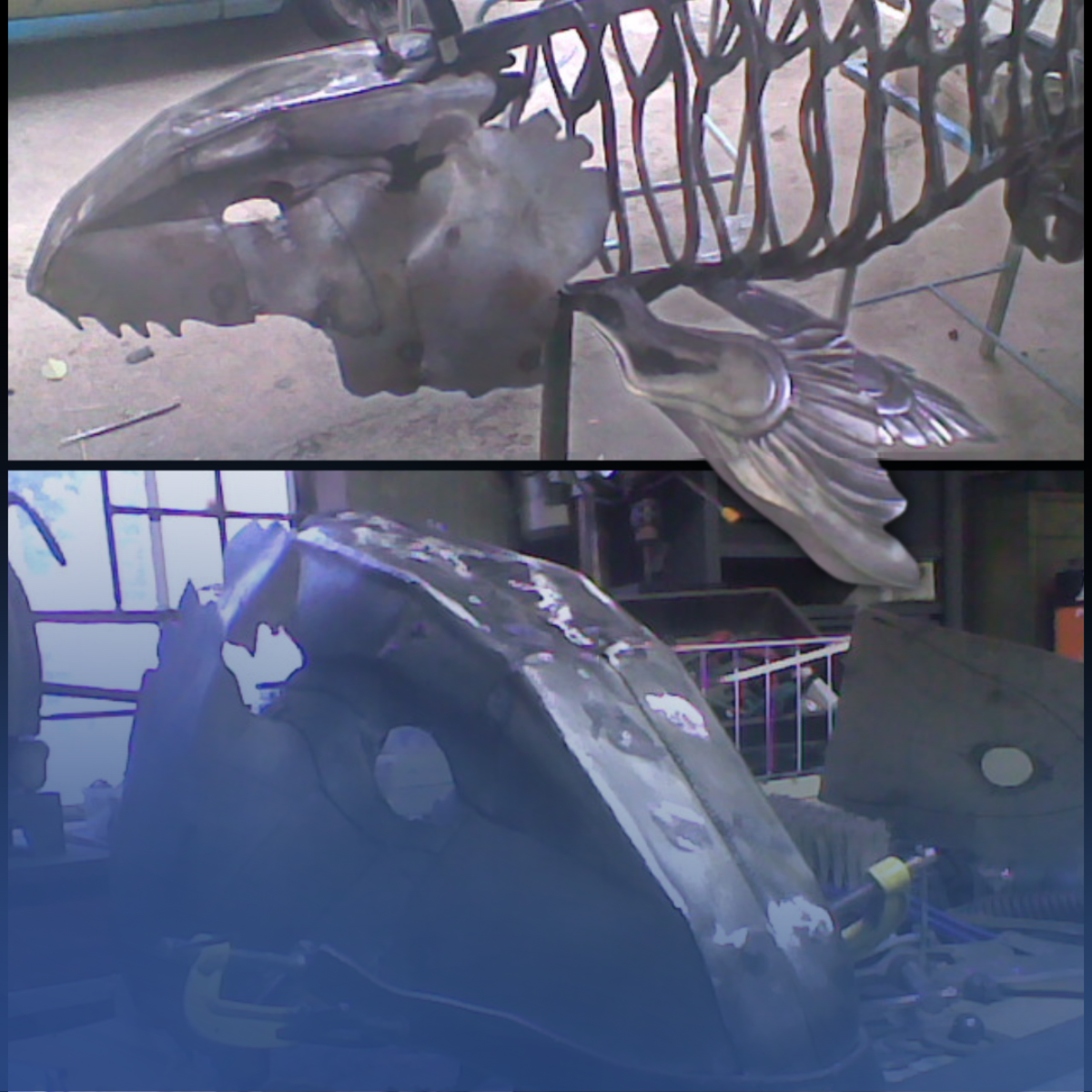

"This is my full steel armour, based on the character Issei Hyoudou.

Made almost entirely out of metal from @njrsteel (excluding the trousers and shirt), this piece is held together with a total of 453 rivets, and I lost count of the internal weld points.

All the armour's patterns were originally designed, measured, cut out, cleaned, polished, and colour-prepped by me — no external templates were used. The hinges used for the mobility of the arms and shoulders were also custom-made using cut-offs from a steel bar from a previous project.

For the finishing touches, the colour was done via powder coating, there are internal LEDs, and the details are all outlined with markers to give the character a hand-drawn appearance.

This was the first big metal/steel project I ever worked on, and it took a total of three years to complete. My affinity for working with metal and steel began when I made a rib cage neck piece when I was 16 years old. Eventually, I decided that I wanted to create an authentic headpiece made entirely out of metal. I became obsessed with the project and the process, and it continued from there until, after much trial and error, I finished with this final piece.

Since working on this project, steel and metal are now my favourite mediums to work with, and I try to incorporate them into any project I take on.

All the metal used in this armour, including the cut-offs, is from @njrsteel, as both my father and I have been loyal to them for years for their high-quality products at excellent, competitive prices and their wonderfully helpful staff.

This was my first big metal/steel project I ever worked on, and it took a total of 3 years to complete.

My affinity for working with metal and steel began when I made a rib cage neck piece when I was 16 years old. Eventually, I decided that I wanted to create an authentic headpiece made entirely out of metal; I became obsessed with the project and process, and it continued from there until, after much trial and error, I finished with this final piece.

Since working on this project, steel and metal are now my favourite mediums to work with, and I try to incorporate them into any project I take on.

All metal used in this armour, including the cut-offs, is from @njrsteel as both my father and I have been loyal to them for years for having high-quality products at excellent competitive pricing and wonderfully helpful staff."

Warren Botten

18 Points

"NJR Steel! Your great service, lowest prices, and free delivery helped make a boyhood dream come true!!"

Warren's Facebook Video

Johnny Schute

18 Points

"Making Proper products requires Proper Materials. Thanks, NJR Steel!

The better way to keep your kids outdoors.

Instead of screen time.

All made of Proper NJR Steel."

Charles Coetser

18 Points

"I live and work on a farm, and I decided to build a small tractor for my son for his 1st birthday.

Only the wheels were bought, and the stickers were printed. The rest was self-made of steel.

The tractor is like a "push cart" and my son loves it so much. I sometimes regret building it."

Peter Spittel

18 Points

"Built this from scratch

I used a Lexus V8 fitted to a Camry front-wheel drive Gearbox.

I use the vehicle to do rock crawling and fun 4x4 trails."

Ilana van Wyk Joubert

18 Points

My Steel Story with NJR Steel

"For my projects, I chose NJR Steel because of its proven quality, durability, and versatility. Steel forms the backbone of so many industries, and in my case, it played a vital role in ensuring both strength and reliability.

The specific work I focused on included building and refurbishing trailers to give them a second chance at life, reinforcing structures, crafting gates, and building mobility scooter ramps for differently-abled individuals — helping them move freely and enjoy life with their families.

For this, I needed material that could withstand everyday wear and tear and stand the test of time. NJR Steel provided exactly that — a trusted product that gave me peace of mind throughout the process.

NJR Steel was easy to work with, supported by a great sales team. Its structural integrity ensured that the finished products not only met expectations but exceeded them.

What stands out most is the confidence I have in choosing NJR Steel — knowing I am supplied by a company that values both innovation and customer satisfaction.

For me, steel is not just a product — it's the foundation of creativity and reliability in every project I do. And with NJR Steel, I know that foundation will always be solid.

We are a husband-and-wife fabrication team, and every project we deliver is tailor-made to meet each client's needs."

Jean Fourie

18 Points

"With a passion for steelwork and an obsession with overlanding 4x4 videos came the dream of an off-roading camper.

Building my own was the answer to achieving my dream. The first design was built around a camping trailer, but that soon changed into a bigger and better design. The frame design consists of a fold-out kitchen on one side and a fold-out bed on the other. The roof lifts to give headspace to stand up in.

Over the last nine months, I have been working in my free time, using products and materials from NJR Meyerton. I used a variety of tubing and channels and will be using aluminium sheets for the exterior, bringing it all together one weld at a time.

The next phases will be to cover the exterior and finish the interior. The last phase will be to take it out into nature and enjoy the muddy roads in and around South Africa."

Graham Rickhoff

18 Points

FEEL INSPIRED?

GET PRICING FROM YOUR NEAREST NJR STEEL BRANCH

We have 21 branches across 7 provinces that are ready and willing to help you. Talk to us today to get pricing or just advice for your next project.

Like What You See?

Search the #NJRMadeOfSteel on Facebook or Instagram to see all the entries!